PRIN. OF INTERNAL COMBUSTION ENGINES - OD1619 LESSON 1/TASK 1

(b) They prevent the lubricating oil from bypassing the piston and getting

into the combustion chamber from the crankcase.

(c) They provide a solid bridge to conduct the heat from the piston to the

cylinder wall. About onethird of the heat absorbed by the piston passes to the

cylinder wall through the piston rings.

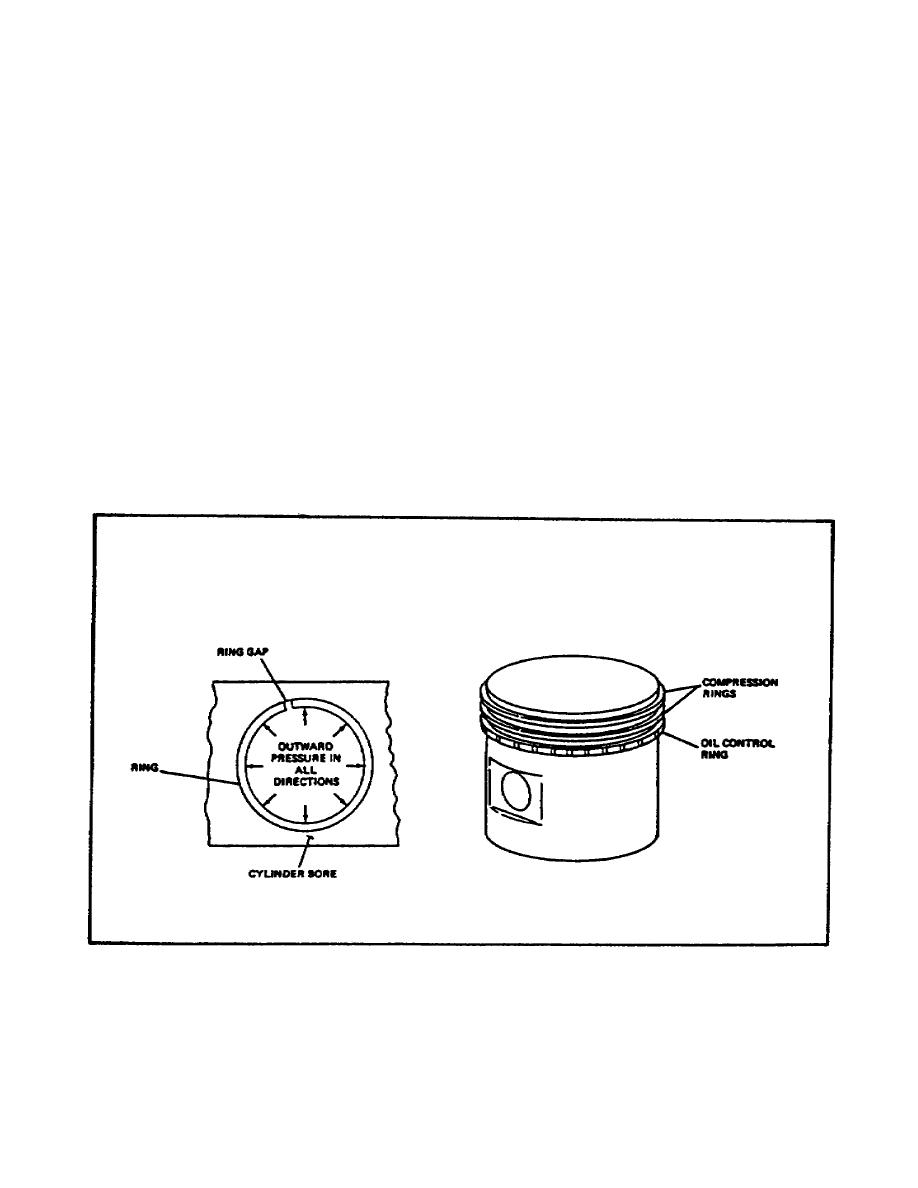

(2) Description (figure 19). Piston rings are split to allow for installation

and expansion, and they exert an outward pressure on the cylinder wall when

installed. They fit into grooves that are cut into the piston, and are allowed to

float freely in these grooves. A properly formed piston ring, working in a

cylinder that is within limits for roundness and size, will exert an even pressure

and maintain a solid contact with the cylinder wall around its entire

circumference. Although piston rings have been made from many materials, cast iron

has proved most satisfactory as it withstands heat, forms a good wearing surface,

and retains a greater amount of its original elasticity after considerable use.

There are two basic classifications of piston rings.

(a) The Compression Ring. The compression ring seals the force of the

exploding mixture into the combustion chamber.

FIGURE 19. PISTON RING TYPES AND DESCRIPTION.

21

Previous Page

Previous Page