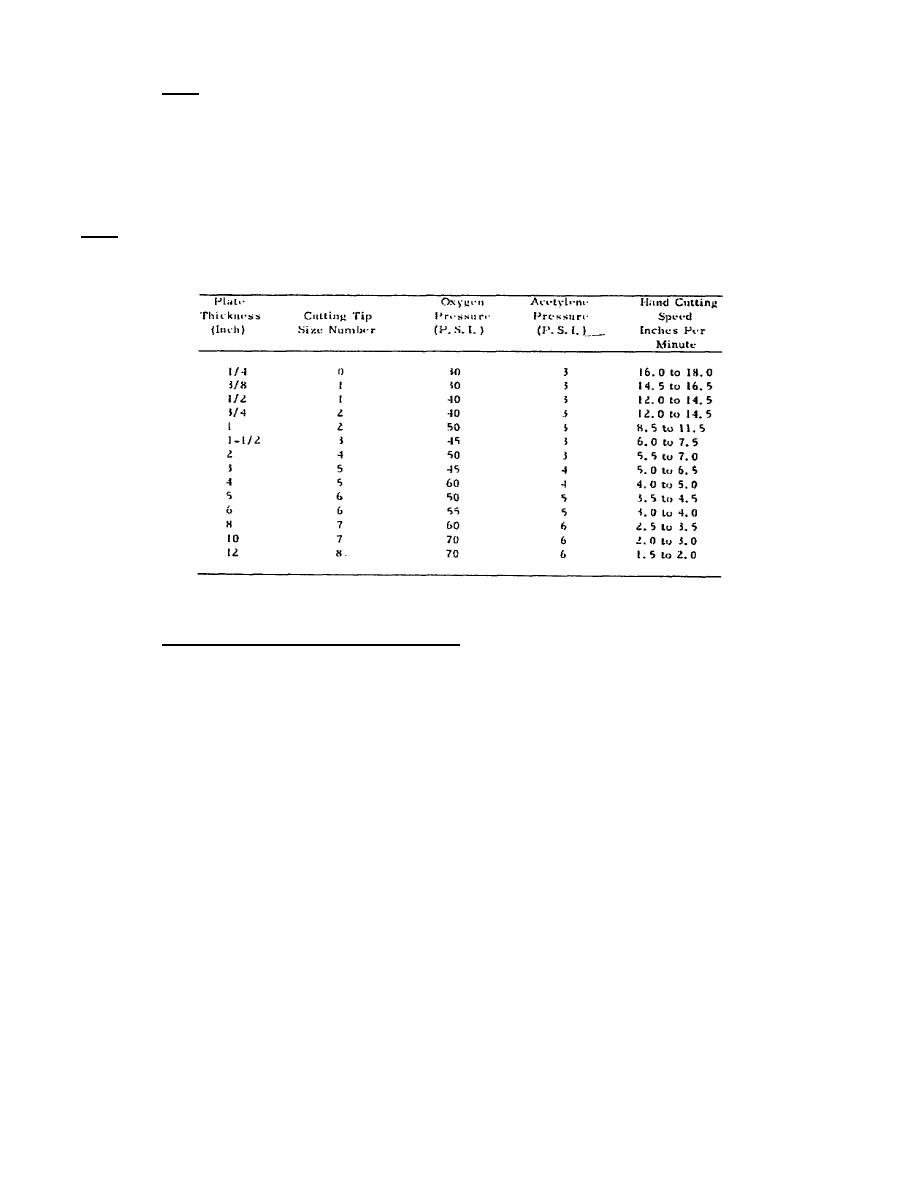

c. Tips. There is a wide variety of cutting tip styles and sizes available

to suit various types of work. The thickness of the material to be cut generally

governs the selection of the tip. The cutting oxygen pressure, cutting speed, and

preheating intensity should be controlled to produce narrow, parallel sided kerfs.

Cuts that are improperly made will produce ragged, irregular edges with adhering

slag at the bottom of the plates. Cutting tip numbers, gas pressures, and hard

cutting speeds used for cutting mild steel up to 12 inches thick are shown in

figure 16.

Note.

-

Various manufacturers do not adhere to the numbering of tips as set

forth in this figure; therefore, some tips may carry different

identification numbers.

Figure 16.

Oxyacetylene cutting information.

d. Protective clothing and equipment.

(1) Clothing manufactured of wool should be worn in preference to cotton

since wool is not easily burned or damaged by weld-metal spatter.

(2) Asbestos cloth or leather aprons or jackets should be worn to provide

protection against the spatter of molten metal, especially when welding in the

vertical or overhead positions.

(3) High-upper shoes and cuffless pants should be worn to prevent spatter

from collecting in the cuffs and to protect the feet.

(4) Gauntlet gloves that are flameproof, preferably of leather, will

protect the arms and hands from weld spatter. These must be in good condition and

free from oil and grease to prevent them from being ignited or charred by molten

metal or hot spatter.

(5) Goggles, spectacles, or helmets with colored lenses should always be

worn when cutting or welding by any process. The colored lenses of the correct

shade, usually blue or brown, give protection from the glare or harmful rays

encountered in arc welding and allow the operator to see the work clearly. A

protective clear cover glass protects the colored lens from damage and must be

changed when damaged or severely pitted by molten spatter.

125

Previous Page

Previous Page